Contents

- Differences Between FR1, FR2, FR3, and FR4 Explained

- FR4: The Most used Type of Material

- Differences in High-temperature Resistance

- The Material Composition of The Main Combination

- Cost-effectiveness

- Differences Between FR3 and FR2

- Materials Suitable for Through-hole Technology

- Materials Suitable for Multilayer Boards

- Summary

Differences Between FR1, FR2, FR3, and FR4 Explained

The main difference between FR1, FR2, FR3, and FR4 PCB lies in the material composition and properties:

- FR1: Made of phenolic resin and paper, suitable for low-cost, low-frequency applications. It has a maximum temperature of 130°C.

- FR2: Similar to FR1 but with slightly improved heat resistance and durability, often used in consumer electronics.

- FR3: Combines phenolic resin and paper with epoxy resin, providing better performance than FR2 but still inferior to FR4.

- FR4: Made of woven fiberglass with an epoxy resin binder, offering superior strength, thermal stability, and electrical insulation. It is the industry standard for most PCB applications.

(a typical PCB board shot in up-close)

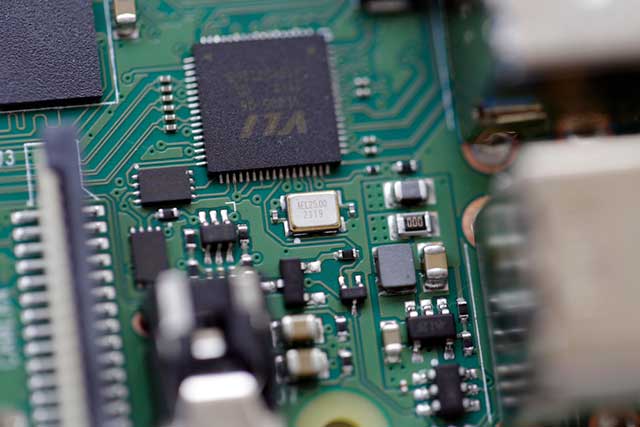

FR4: The Most used Type of Material

FR4 is the most popular one. FR4 is a glass fiber epoxy laminate and the most widely used base material after FR1 and FR2.

Without a doubt, FR4 is the best choice of material to use. A majority of designers like it when it comes to the production of printed circuit boards. FR4 material is excellent for passing through-holes, making it a perfect fit for Through-Hole PCB Assembly processes. Unlike FR1, FR2, or FR3 materials, the FR4 does not pose challenges or difficulties.

FR4 is a popular choice for creating all types of printed circuit board layers, from one-layer to multilayer PCBs, and is often used in High-Frequency PCBs requiring high-speed signal integrity and superior electrical and thermal performance. FR4 is suitable for applications that demand flexibility or regular flexing. For applications requiring enhanced adaptability, Flexible PCBs are an excellent option, as they incorporate FR4 materials to ensure durability and performance. FR4 material is also ideal due to other reasons. Devices such as USB connectors, Bluetooth accessories rely on FR4 material.

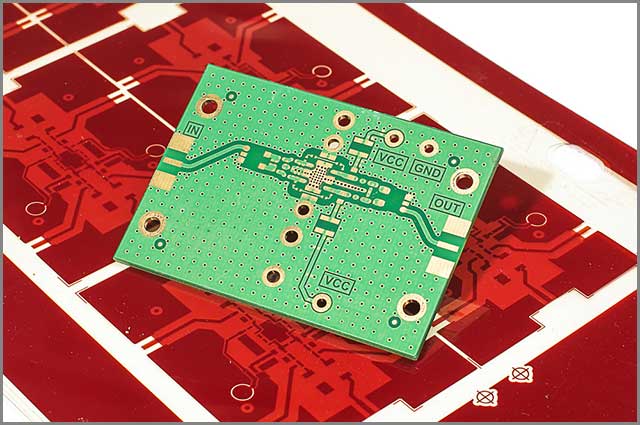

(a sample of the FR4 material on a PCB)

Differences in High-temperature Resistance

There are different types of materials used in the production of PCBs, depending on the specific conditions. For instance, the type of material used in the manufacture of electronics differs from those used in military applications.

Some materials are suitable for high-temperate environments.

Besides, some are ideal where vibrations are vigorous. PCH heat resistance is another factor that tells apart FR1, FR2, FR3, and FR4 materials. When it comes to temperature resistance, you can count on FR4 material for the best results compared to the rest.

FR4 contains printed circuit board materials suitable for extreme temperature environments. Products that experience high thermal loads or working in the range of 130 degrees Celsius are good with FR4 material. If you happen to work with some high power density designs, a high-temperature PCB made of FR4 material is the only answer.

(FR4 materials are excellent conductors of heat and can also maintain their composure)

Special Offer: Get $100 off your order!

Email [email protected] to get started!

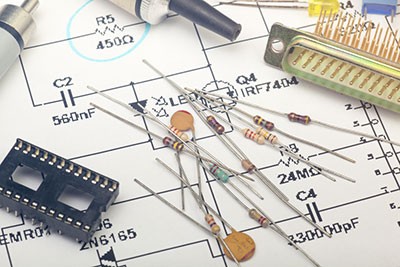

The Material Composition of The Main Combination

Material composition is one of the crucial differentiating factors between FR1, FR2, FR3, and FR4 PCBs. There are several types of materials. Plenty of them is readily available in the market. But understanding material composition poses a challenge to many people.

FR1, FR2, FR3, and FR4 materials differ in heat resistance, electrical strength, and thermal properties, to mention but a few. Materials used in PCBs production from top to bottom are Silkscreen, Soldermask, Copper, and finally, Substrate. There are cheaper PCBs on the market which don't use the materials mentioned above.

For instance, the material composition of FR3 material is epoxy resin binder instead of the phenolic resin used in FR2 material. On the other hand, the material composition of FR4 is glass fiber epoxy laminate. Thus, material composition is another factor that sets aside FR1, FR2, FR3, and FR4 materials on a PCB.

(The composition of the material dictates the overall quality of the PCB)

Cost-effectiveness

The materials used in the production of printed circuit boards remain essential. There are some which are a little bit cost-effective than others. Costs of different materials can range from 10% to 100%. Cost is a factor that can affect the price of a printed circuit board. For example, FR1 and FR2 materials don't differ at all. They are the same type of material with similar cost-effectiveness.

When it comes to PCB production, a majority of manufacturers opt to use FR4 material. The main reason for this is because FR4 material is cost-effective. The rest cost a little bit more. With FR4 materials, printed circuit board companies can cost-effectively manufacture all types of PCBs.

(The Overall quality dictates the cost-effectiveness of the PCB)

Differences Between FR3 and FR2

There are striking differences between FR3 and FR2 materials. Phenolic resin and hard paper are the material that makesFR2. Phenolic and hard paper is a cheap material formerly used in high-volume production of printed circuit boards. But phenolic resin is not used anymore since based on its qualitative deficiencies.

Phenolic resin is known for emitting small amounts of formaldehyde and phenol. Such represents a considerable health risk.

On the other hand, epoxy resin and hard paper are the materials that make FR3. Epoxy resin and hard paper are budget-priced materials that are ideal for printed circuit board manufacturers operating on a budget. Again, FR2 is ideal for one-layer printed circuit boards since they aren't excellent for passing through-holes.

(The epoxy resin is one of the features that separates FR3 from FR2)

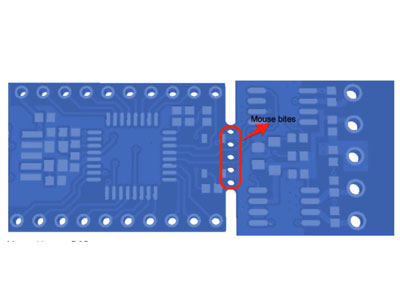

Materials Suitable for Through-hole Technology

Through-hole technology, also spelled as thru-hole, is a mounting scheme used in many electronic components. Through-hole involves the using leads that require insertion into the holes drilled on the printed circuit board. The components then need some soldering to pads that are on the opposite side. This can is achievable either manually or by the use of specialized equipment.

While most designers have attempted using FR1, FR2, and FR3 and passing them through thru-hole, the results haven't been excellent as such. For this reason, PCBs made from FR4 is ideal when it comes to passing through-holes in them. Again, materials suitable for through-hole technology differentiate FR1, FR2, FR3, and FR4 materials from each other.

(Thru-hole is ideal for FR4 materials as compared to FR1, FR2, FR3)

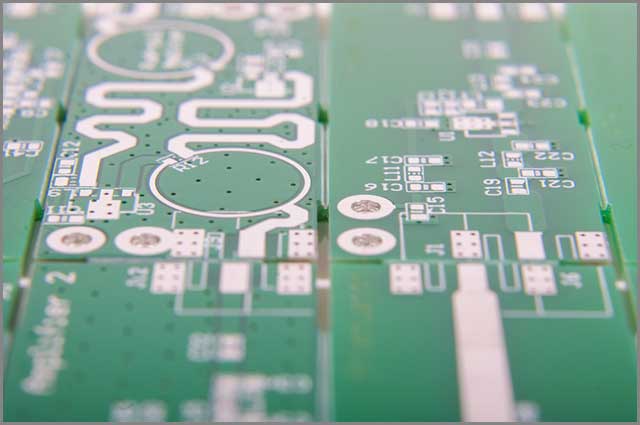

Materials Suitable for Multilayer Boards

Certain types of material are highly ideal for multilayer boards, while others aren't. Multilayer PCBs are those boards that consist of three on more layers in them. Multilayer printed circuit boards may consist of boards consisting of 32 layers.

While all FR1, FR2, and FR3 materials have manufactured multilayer PCBs, FR4 material is one of the most widely used. Many designers prefer FR4 material based on the fact that it's ideal for making all types of PCBs. Although some materials (such as FR2 and FR3) may be cheaper than FR4 materials, FR4 is still the favorite of many designers.

Sifted through, multilayer PCBs made of FR1, FR2, and FR3 material lack reliability and stability. For this reason, it's good to go for FR4 materials. All in all, materials that are ideal for multilayer PCBs is another factor that differentiates FR1, FR2, FR3, and FR4 materials that are common in the manufacture of PCBs.

(The FR4 is the best material for multilayer PCB)

Summary

Which types of printed circuit board materials do you need? We can provide all types of materials based on your project. For more than a decade, we have provided FR1, FR2, FR3, and FR4 materials to our vast pool of customers.

If you need your PCBs made using the material of your choice, you can trust us at OurPCB to deliver. To get started, all you have to do is contact our friendly and responsive customer care attendants for assistance.

Call us for a quick quote, and let us know all that you need. We at OurPCB are ready to assist you at any time without failure.

Special Offer: Get $100 off your order!

Email [email protected] to get started!