Printed Circuit Board PCB Assembly Manufacturer

Bring your PCB design ideas to life effortlessly with our comprehensive services.

- High-quality PCBA (IPC-A-610 Class 3)

- Small & medium orders skillfully executed

- Exceptional insight & deep expertise

- Seamless communication

- Transparent BOM, PCB, & PCBA pricing

- Client-focused flexibility (photo, video)

Get Free quote now

Welcome to OurPCB - PCB Assembly Manufacturer

We’ve been a top-tier Printed Circuit Board Manufacturer since 2007, and we’ve worked with some of the most innovative companies in the world, especially in the USA. From component sourcing to final assembly and testing, we’re ready to bring your PCBs to life.

Square Meters

Work Space

Factories in China

Years With PCB

Solutions

Customers

Worldwide

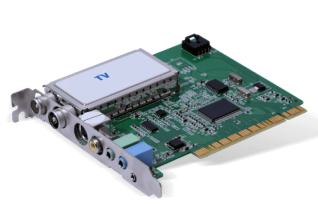

- PCB Assembly Services: Comprehensive solutions for assembling printed circuit boards.

- Quick Turn PCB Assembly: Fast and efficient PCB assembly to meet tight deadlines.

- High Volume PCB Assembly: Scalable solutions for large-scale PCB production.

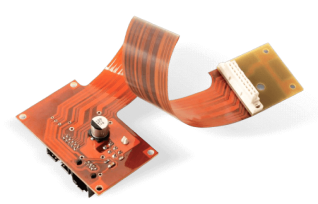

- Flexible PCB Manufacturer: Specialized in manufacturing flexible PCBs for diverse applications.

- Low Volume PCB Assembly: Cost-effective solutions for small batch PCB assembly.

- Turnkey PCB Assembly: End-to-end services covering all aspects of PCB production.

- PCB Design Services: Expert design services to bring your PCB concepts to life.

- Rigid-Flex PCB Manufacturer: Manufacturing robust and versatile rigid-flex PCBs.

- PCB Prototype: Rapid prototyping services to test and refine your PCB designs.

- Rogers PCB: High-frequency PCBs ideal for RF and microwave applications.

- Aluminum PCB: PCBs with excellent heat dissipation properties, perfect for high-power devices.

- Metal Core PCB: Thermal PCBs with metal bases for effective heat management.

- High Tg PCB: High glass transition temperature PCBs for improved thermal performance.

- High Frequency PCB: Designed for high-speed and high-frequency applications, ensuring superior signal integrity.

- Heavy Copper PCB: Built with thicker copper layers for high current and enhanced thermal management.

- HDI PCB: High Density Interconnect PCBs offering advanced circuitry in a compact design for complex applications.

- Traceability processing of PCB 2D code laser marking

- ISO 9001:2015 certified

- RoHS & lead-free assembly

- Consigned components or turnkey

- Single- or double-sided mixed technology PCB assembly

- All IC packages (BGAs, CGAs, QFNs, DFNs, CSPs)

- From authorized distributors only

- Capacitors and resistors in stock

- For large quantities: Arrow, Avnet, Future Electronics

- For prototypes: Mouser, Digi-key, Element14

- Up to 64 layers

- Finished Copper: 1000um

- Min. Line/Track Width: 1.8 mil

- Min. Line/Track Space: 1.8 mil

- Finished Board Thickness: 0.1 to 12 mm

- Min. Drilling Size (Mechanical): 0.1mm mm

- Tolerance PTH (Pressing fit hole) NPTH: +/-0.0762 mm / +/-0.05 mm / +/-0.05 mm

- Custom wire harnesses and custom hybrid cables

- Retrofit existing cables with robust connectors, shielding, and carriers

- Availability of off-the-shelf cable assemblies

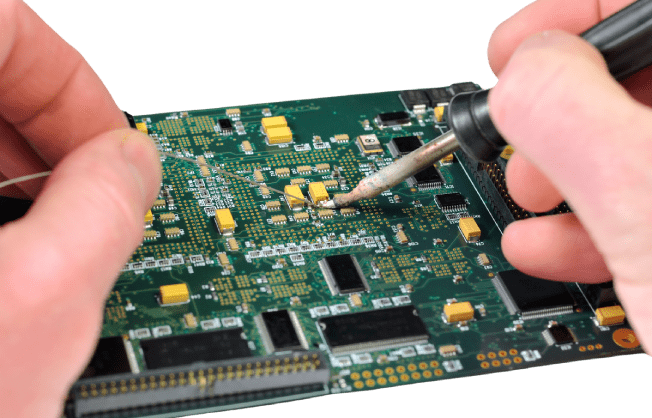

- Static and functional testing

- AOI and X-ray inspection

- Thermal stress test

- Impedance test

- Solderability test

- Solder mask hardness test

- RoHS testing

- Custom Prototyping

- Cost-Effective Production

- Material Variety

- Quality Assurance

- Diverse Applications

More Circuit Boards & Assembly Manufacturing Services

OurPCB provides comprehensive circuit board manufacturing solutions tailored to your specific project requirements. Our expertise spans from PCB assembly services in both low and high volumes to specialized manufacturing with materials like Rogers, aluminum, and metal core PCBs. We offer quick-turn and turnkey assembly options alongside professional PCB design services to ensure optimal performance and manufacturability. Whether you need high frequency boards, heavy copper PCBs, or HDI technology, our team delivers quality prototypes and production runs with precision and reliability.

Why Choose OurPCB?

Long History of Trusted PCB Assembly Manufacturing Services

We’ve been in the industry since 2007, and have served over 3,000 happy customers.

Dedicated Account Manager

Every customer order is paired with a dedicated account manager who assists with order placement and production initiation while ensuring smooth delivery and reliable after-sales support.

Fast Quoting System

Bare PCB quotes will be in your inbox within 8 working hours. PCBA with components take up to 2 working days.

Top-Class PCBA Factories

Our factories span 10,000 m² each (ISO 9001, IATF 16949, IPC-A-610 Class 2 and 3 certified). We also have a fully equipped wire harness factory (ISO 9001, IATF 16949, and IPC/WHMA-A-620A certified).

Meet International Industry Standards

We’re UL-certified, we meet RoHS directives (lead-free soldering), and we meet all international industry standards (ISO 9001:2015, ISO 13485:2016, IATF 16949:2016, IPC-A-610)

Original, Premium-Quality Components

We source only the best original components from authorized providers, including Mouser, Digi-key, Future Electronics, and WPG Holdings.

Your One-Stop PCB Assembly Manufacturer

We’ve got you covered for bare PCB manufacturing, PCB assembly, wire harness manufacturing, casing/housing manufacturing, component sourcing, and programming/testing.

PCB Manufacturing & Assembly Process

Online Quote

Upload

Gerber File

Payment

Production

Delivery

Order

Complete

The process begins the moment you upload your files and get a free quote from OurPCB Assembly Manufacturer. Our full end-to-end process includes:

Design for Manufacturing (DFM) Review

Complete DRC checks of all client files to identify potential problems. We then work with you to correct the files so they are suitable for manufacturing.

Component Sourcing

We stock common components and purchase authorized parts if not in stock. You can also order directly from suppliers and ship them to our assembly plants.

Fabrication of Bare PCBs

You can send your bare PCB for assembly or contract us to fabricate the board. We can manufacture PCBs with 1 to 64 layers.

Assembly

Our comprehensive services include low- to high-volume, flexible, rigid, and rigid-flex, single- or double-sided mixed technology assembly, and all IC packages (BGAs, CGAs, QFNs, DFNs, CSPs).

Testing & Inspection

We thoroughly test your PCBs. Our tests include: flying probe test/fixture test, impedance test, solderability test, thermal shock test, hole resistance test, and micro metallographic section analysis.

Shipping & Delivery

Once your PCB is ready, we’ll ship it to you in a secure, custom package that’s shock-resistant and waterproof to protect the circuit in transit.

What Our Clients Say

Based on 155 reviews

Blog

Top 7 Truck Wiring Harness Manufacturers

Truck wiring harnesses are the electrical backbone of commercial vehicles, from long-haul trucks to construction fleets and emergency vehicles. They

Top 11 Medical Device Cable Manufacturers

Medical cable assemblies sit at the intersection of electrical safety, biocompatibility, and sterilization durability. For regulated medical devices, OEMs must

Top 10 Robotics Cable Assembly Manufacturers

Robotics cable assemblies are unlike ordinary cables, they must survive continuous motion, tight bend radii, torsion, vibration, electrical noise, and

Take a Factory Tour!

OurPCB’s manufacturing journey began with our Shijiazhuang factory in 2007. This factory spans over 10,000 meters, 90% of which is dedicated to advanced PCB assembly services. Over 300 skilled technicians manage 5 SIEMENS SMT lines to produce top-notch PCBS for affordable prices.

As OurPCB grew, we needed to expand our facilities and production capacity. In 2017, we built our second factory in Shenzhen to increase our standard PCB assembly services. This factory is 5,000 square meters and has 8 YAMAHA SMT lines, including X-ray and AOI capabilities. The production line employs 110 dedicated staff to meet your PCB assembly needs.

We’ve expanded our services to English-speaking customers worldwide. In 2014, we opened OurPCB in Melbourne, Australia, to provide PCB assembly services to Australian and international clients. Join us in bringing your projects to life with OurPCB!

Frequently Asked Questions

What is the Difference between PCB Manufacturing and PCB Assembly?

PCB manufacturing focuses on constructing the board itself, whereas PCB assembly involves adding electrical components to the PCB to make it work.