Laser cutter uses are versatile devices with multiple applications in engineering and art because you can use them to cut, etch, or mark. But they come in different types, each ideal for working on specific materials. We will look at the laser cutter uses and the laser cutting machines you can use for each material. Let's get right into it!

Contents

- What Is a Laser Cutter?

- How a Laser Cutter Works

- Types of Laser Cutters

- CO2 Laser

- Neodymium Laser

- Fiber Laser

- What You Can Do With A Laser Cutter

- Cutting

- Marking

- Engraving

- Laser Cutter Settings

- Speed

- Power

- Frequency

- Resolution

- Laser Cutter Uses: Crafty Applications

- Wooden Keychain Holders

- Keychain Bottle Opener

- Wine Glasses

- Coasters

- Wood Rolling Pin

- Acrylic Wax Seal Matrix

- Glass Spice Jars

- Shadow Box

- Wooden Puzzles

- Acrylic Ornaments

- Paper Art

- Felt Rugs and Pillows

- Acrylic Stands

- Wooden Signage

- Wrap Up

What Is a Laser Cutter?

A laser cutter is a type of Computer Numerical Control (CNC) device that uses a focused, thin laser beam to cut through different materials. Most artists, engineers, and designers use these laser machines to cut and etch flat materials for prototyping and manufacturing.

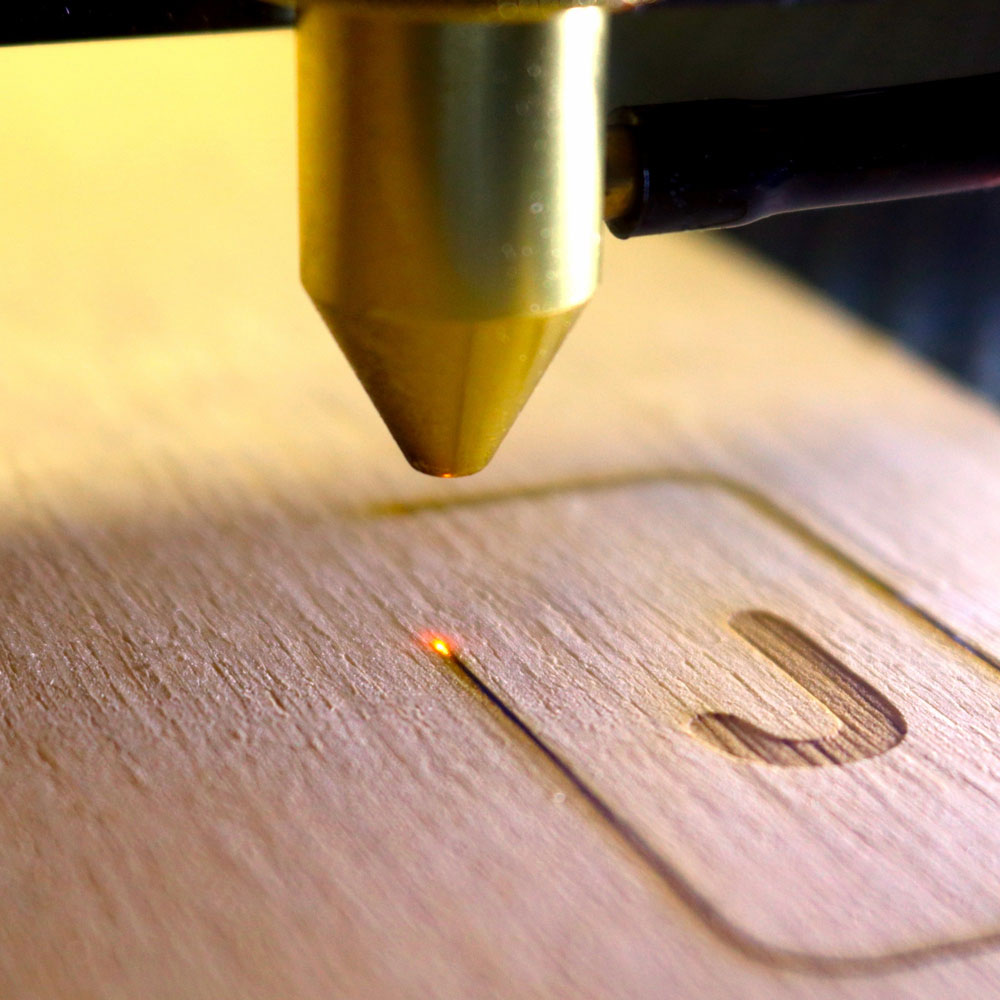

A CNC laser cutter in action

How a Laser Cutter Works

Although these CNC machining devices come in different types, they use the same process to cut materials using a laser beam. The process begins with a laser resonator. It produces an intense laser beam that reflects on a mirror system to the laser head. The laser head narrows the laser down to a thin beam using a lens. This narrow beam goes out of the head and projects down to the material, cutting or etching it.

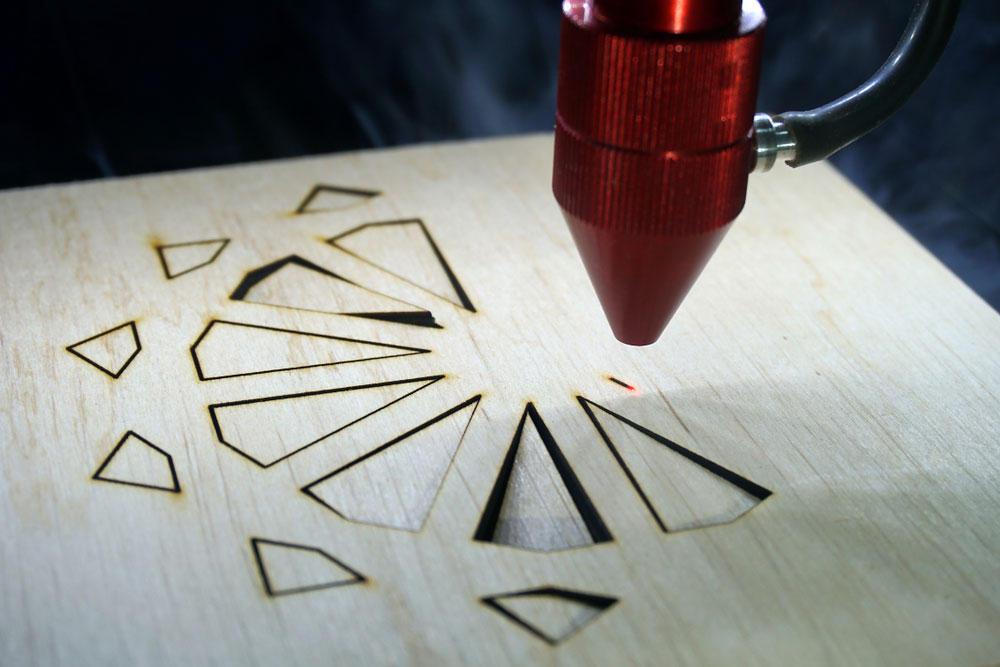

Intricate snowflake designs created by a laser cutter

An XY gantry holds the head for positional movement. A gantry is a belt or chain-driven mechanical system that moves the head precisely over the material to match the design from the computer.

But for the laser to cut, the lens focal point should be on the material you are machining. So these laser machines require a focusing procedure before use to ensure it cuts accurately.

Special Offer: Get $200 off your order!

Email [email protected] to get started!

Types of Laser Cutters

The three primary laser cutter types have varying power outputs, which define the range of materials the device can cut through. They include the following.

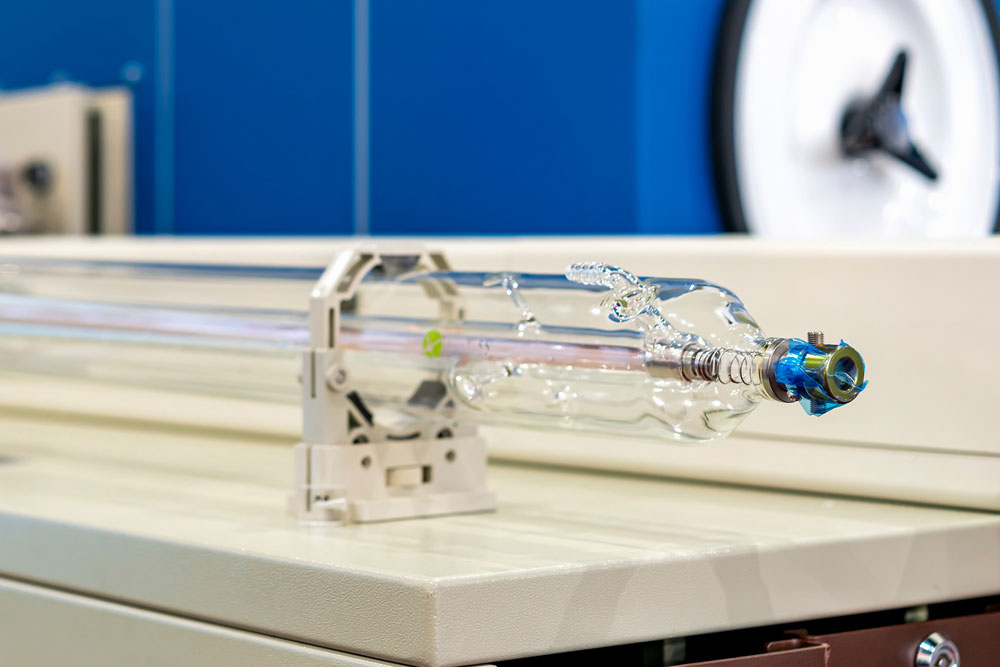

CO2 Laser

This device generates its laser from electrically simulated gas mixtures that mostly contain carbon dioxide. It is the most typical type of laser cutter due to its affordability, low power, and efficiency. Additionally, it can cut through several materials, such as the following.

- Wood

- Acrylic

- Leather

- Some plastics and foams

- Paper-based products like cardboard

- Anodized metals (raster operations)

A CO2 laser tube for creating a laser beam

Neodymium Laser

This cutter generates the laser beam using neodymium-doped crystals. It can have shorter wavelengths than CO2 lasers, implying a higher beam intensity. So it can cut through thicker and stronger materials, like ceramics, metals, and plastics. However, the high power makes the parts wear out quickly. So it needs frequent parts replacement.

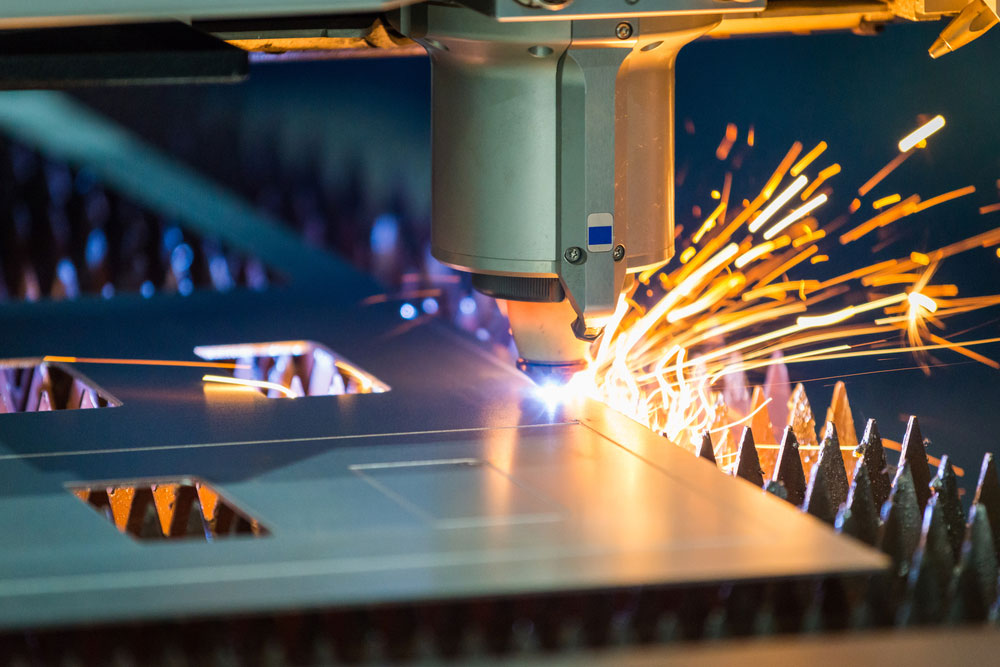

Fiber Laser

These devices generate the laser using a seed laser then special glass fibers amplify it. The intensity and wavelength of the produced beam are similar to the ones in the neodymium laser. However, they require way less maintenance. The cutter is typical in laser marking processes in plastics and metals.

A fiber laser cutting machine

What You Can Do With A Laser Cutter

You can perform these three operations using laser machining technology.

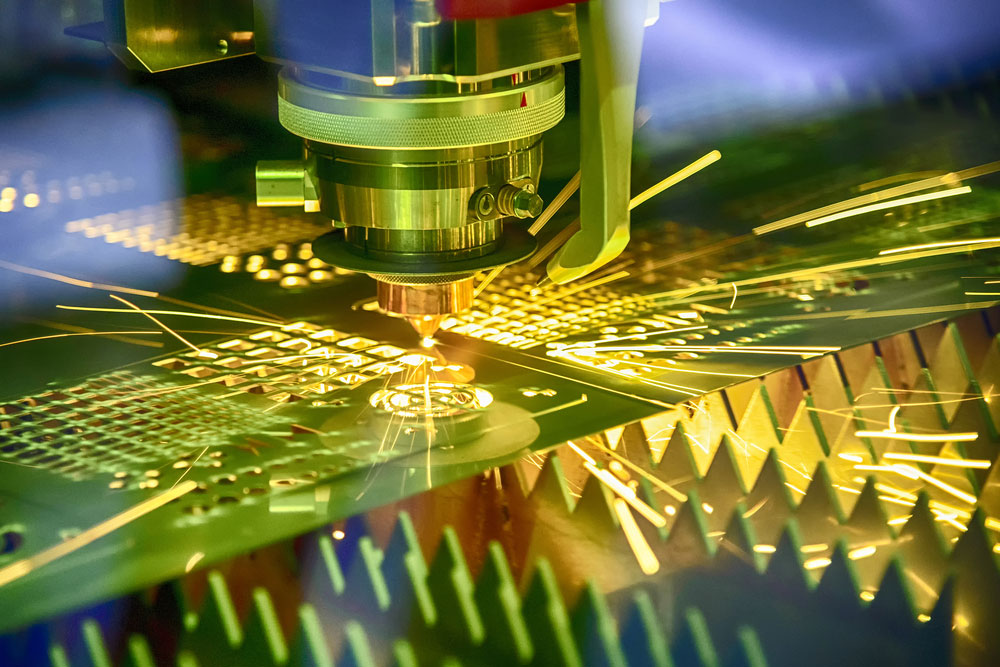

Cutting

Cutting is when the beam goes through the workpiece. Each machine usually has its kerf rating that determines the maximum material thickness it can cut. And it can create angled kerfs if the material is too thick. But generally, the kerf or groove is usually thin when cutting most materials (0.05-0.5mm).

A CNC laser cutter is machining a metal sheet.

Marking

Marking occurs when the laser does not etch any material. Instead, it only changes the color. CO2 laser cutters are typical for marking metals like stainless steel and mild steel. The process involves applying a marking solution on the surface then the metal goes under the laser. The heat from the laser bonds the fluid to the metal, creating a permanent mark.

Engraving

Engraving sits between cutting and marking. It involves removing part of the material's top layer without cutting through.

The engraving process using a laser cutter

Laser Cutter Settings

Laser engravers have four primary settings that determine the quality of the technical design. These include the following.

Speed

Speed defines how quickly the laser head moves along the gantry. High-speed settings will make it move faster, but it will not cut deep or through to the other side if you are dealing with thicker material.

Low speeds will focus the intense light for longer to cut through. But it can melt or burn the edges of the laser-cut pieces. Raster operations typically use high speeds but can wear out the gantry if working on large workpieces.

Power

High-power lasers will cut through hard items faster. When engraving, they burn more layers into the laser-cut material, creating darker images.

However, they can burn thin or flammable materials like wood or cardboard. Some materials can also produce toxic fumes as they burn.

On the other hand, low-power lasers might not be powerful enough to create deep laser engraving or cut through.

Frequency

You can only use this setting for the laser-cutting process. And it determines how quickly the laser pulses when cutting. The beam turns on/off rapidly, and higher frequencies create cleaner cuts. However, these high frequencies can burn the material if it is flammable. So use lower frequencies when dealing with these materials.

Resolution

Only use this setting for raster operations because it determines the quality and resolution of the raster. Higher resolutions create darker images that look more refined if you concentrate the heat in one area. However, too much heat can melt, burn, or damage the laser-cut piece.

Laser Cutter Uses: Crafty Applications

Whether prototyping or manufacturing, you can use Adobe Illustrator or other design software to bring designs to life with a laser cutter in the following applications.

Wooden Keychain Holders

Wooden keychain holders are usually plywood, and you can use simple laser cutting and engraving to create design ideas and writings on the surface. The cutting will come on the edges to darken the sides.

Plywood cutting and engraving using a laser cutter

Keychain Bottle Opener

Like the keychain holders, you can engrave stainless steel bottle openers to gift your guy friends or groomsmen after your wedding.

Wine Glasses

Regular wine glasses look simple and okay, but you can add a little sophistication by engraving intricate designs on the surface. But you need a rotary device to hold the glasses when etching because they are not flat.

A wedding glass is etched to match the occasion.

Coasters

Try creating initials, sayings, patterns, or geometric shapes like mandalas on coasters. The possibilities are endless.

Wood Rolling Pin

Rolling pins are essential for making different pastries. Instead of using a flat one, engrave complicated shapes on the surface to bake unique Christmas cookies for the holidays.

Acrylic Wax Seal Matrix

A seal maker or matrix is usually an acrylic laser-cut structure. Although nobody uses these matrices to make wax seals for postage anymore, you can use them to create artwork for weddings and other events.

Glass Spice Jars

It will look classier if you mark/etch glass spice jars instead of labeling them using paper. Alternatively, you can engrave the spice content names to personalize the jars and give them character.

Shadow Box

You can give collection/shadow boxes some character by etching words or designs relevant to the collection.

A laser cutter cutting plywood

Wooden Puzzles

Who doesn't love puzzles? They are especially vital for kids, so a laser cut machine would be a worthy investment if you run a school.

Acrylic Ornaments

Ornaments are personalized objects that show people's interests. So they can be the ideal gifts or items you place on your rearview mirror, trees, etc.

Paper Art

You can use laser-cut machines to create geometric laser-cut products using paper because they are precise.

Paper art created by a laser cutter

Felt Rugs and Pillows

Laser-cut machines can cut or engrave intricate models that create 3D shapes on textile pieces like felt rugs. You cannot cut through leather pillows, but etching can create geometric shapes with two-tone colors on the surface.

Acrylic Stands

This project is interesting. Instead of only cutting, marking, or engraving materials, you can cut acrylic pieces, then assemble them to make stands. Try making a laptop stand to use the device in bed or on the couch.

Wooden Signage

Neon, LED, and paint signage are impressive. But you might please more customers if you place wooden signage outside your shop/store. If it is not good enough, try engraving acrylic or metal.

Bitcoin signage creation using a CO2 laser cutter

Other projects include the following.

- Pet collar info

- Wedding invitation cards

- Business Cards

- Rubber stamps

Wrap Up

There you have it! The laser technology in laser cutting machines might be different, but the functions of these devices remain the same. So you can use them to cut, engrave, or mark various materials in various projects, as shown above. Contact us if you need assistance, and we'll give you some options.

Special Offer: Get $200 off your order!

Email [email protected] to get started!