Desoldering pumps are physically operating device that removes solder from PCB. The inverse procedure of soldering is desoldering. Therefore, the soldering process involves taking away PCB-mounted soldering and components. Every expert in the tech industry needs to know the method of desoldering a PCB and the best tool to choose. Besides, desoldering is an essential skill, and messing with the process isn’t improbable. Hence, we will tackle desoldering methods, advantages, the best pumps, and much more.

Contents

- Desoldering Methods

- Desoldering braid / Solder wick

- Desoldering pump

- Desoldering gun

- Hot-air rework station

- Desoldering tweezers

- Chip Quik

- Soldering iron only

- Benefits of Using a Desoldering Pump

- Drawbacks of Using a Desoldering Pump

- How to Use a Desoldering Pump

- Step 1: Priming the Pump

- Step 2: Activating the Pump

- Step 3: Desoldering a Joint

- Step 4: Cleaning the Desoldering pump

- How to Desolder a Circuit Board

- Choose Precise Soldering Iron

- Purchase Proper Circuit Board Holder

- Use Solder Vindicated Magnitudes

- Be Prompt

- Disconnect the Circuit Board

- Best Desoldering Pumps

- TABIGER Desoldering Wick & Pump

- Solder Sucker- desoldering pump

- TBBSC Desoldering Pump Solder

- Les now Solder Sucker Desoldering Pump

- Summary

Desoldering Methods

Generally, the process consists of several methods. Here are the frequently used methods.

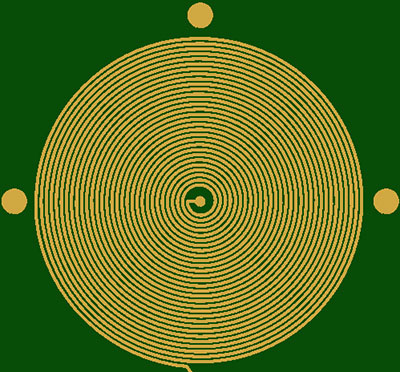

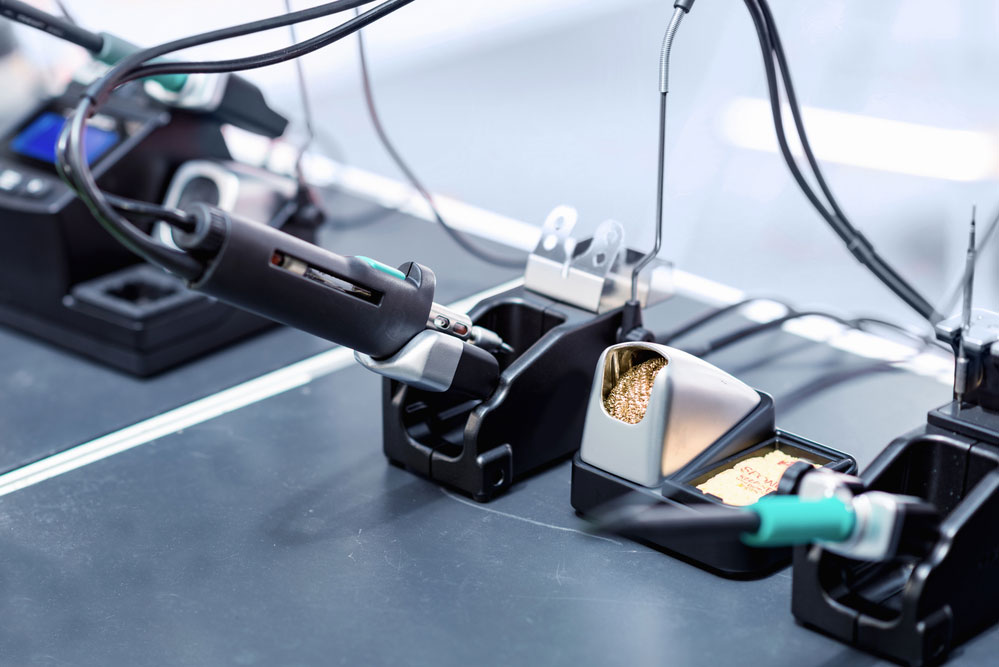

Soldering and desoldering of electronic components

Desoldering braid / Solder wick

The methods work in amalgamation with a soldering iron to take away solder from solder modules and intersections. Usually, it’s a device comprising tinny copper cables layered with flux and weaved. Furthermore, the major benefit of the desoldering wick is that it's affordable and uncomplicated.

Desoldering pump

Also known as a solder sucker, it's a physically operated device that takes away solder. In addition, it uses force by pressing a switch to absorb molten solder positioned within the flame-retardant outlet.

Desoldering gun

The adaptable desoldering gun features a trigger. Therefore, pressing triggers a vacuity pump, sucking the molten solder out via the outlet. Similarly, like the desoldering pump, it generates a vacuum using an electric vacuum desoldering pump rather than a physical nozzle structure.

Electric Vacuum Solder Sucker Desoldering Pump

Hot-air rework station

The method pumps the air using an air pump via a pipe. Besides, using sizzling air, it desolders or solders electrical modules. In addition, to get the ideal outcomes, it regulates its airflow and temperatures using the nozzle.

Desoldering tweezers

Also referred to as hot tweezers, the tools desolder trifling modules with dual soldering rods such as capacitors, resistors, and SMD diodes. It’s easy to melt solders by adjusting the space manually within two desoldering tweezers heated tips.

Chip Quik

A tool that allows you to mix and melt with existing solder on single element pins. Besides, it minimizes the solder melting temperature hence maintaining its molten longer. In addition, it enables you to remove SMD constituents easily without causing damage with soldering irons.

Soldering iron only

Having a soldering iron alone, you can desolder without using tools designed specifically for desoldering. Nevertheless, it can’t give exceptional results due to overheating the solder pads. Nonetheless, it’s a practical preference once there are no other accessible separate tools.

Soldering kit

Benefits of Using a Desoldering Pump

- Its design best suits even the tiny spaces

- It eliminates the necessity of using a separate tool for desoldering the board and liquefying solder once equipped with a built-in heat gun.

- Ease the repairing and troubleshooting process

- The desoldering pumps don’t harm the entire PCB

- The sustainability feature specifies the PCBs recycling prospects for a different mechanical device

.

Special Offer: Get $200 off your order!

Email [email protected] to get started!

Drawbacks of Using a Desoldering Pump

The device has one major drawback: its rubber bulb-style desoldering pumps. Therefore, you may be required to remove faulty parts. In addition, the new PCB devices are ultra-small, making it hard to access some areas. Hence, you may have to find a tiny tip to complete desoldering process.

How to Use a Desoldering Pump

There are vital steps you must follow to use the tool successfully.

Step 1: Priming the Pump

First, begin by priming and galvanizing it several times so it can be ready for desoldering tasks. It will help to activate the pump.

Hold the desoldering pump firmly with your hand. Exert some pressure on the nozzle until it sticks in position, ensuring you press it slightly for suction. As a result, it zeniths the spring-loaded piston.

Step 2: Activating the Pump

On the side part, there is a black button; press it to actuate the pump. It discharges the spring-loaded piston, forming a burst eruption within the plunger. Brace your hand to maintain the plunger's steadiness when using the pump. Note that when releasing the piston, it produces extensive kickback.

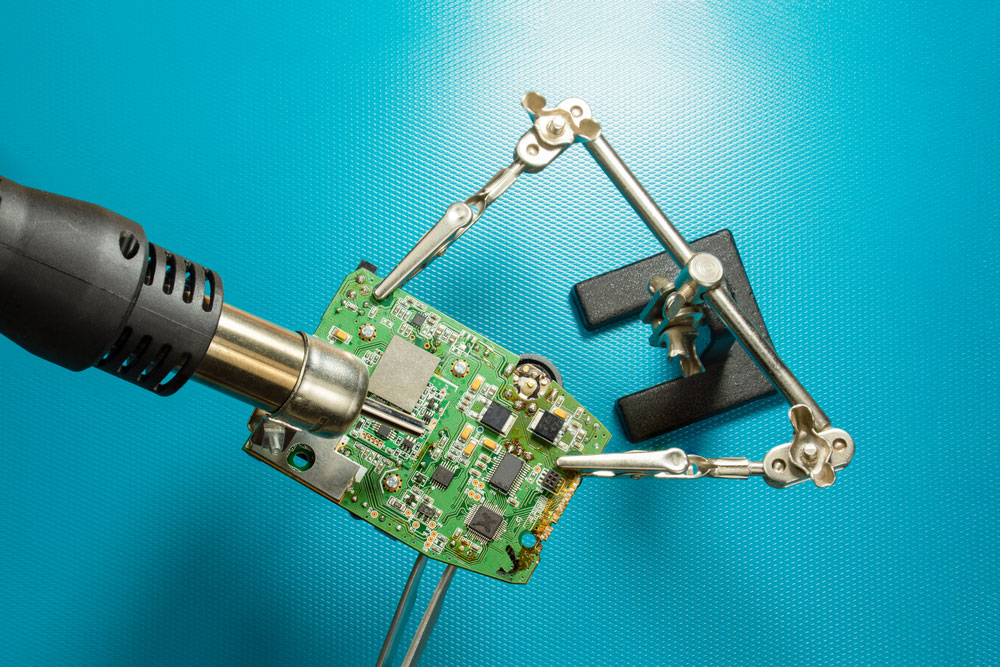

Vacuum Desoldering Pump

Step 3: Desoldering a Joint

After fixing the angled nozzle, tighten the desolder pump. In addition, to ensure the solder liquidities, heat the solder. Put more solder on the linking angle of the desoldering iron to assist with the conduction of heat. Place the pump’s plunger very near to the liquefied solder. To activate the pump, you need to press the side release button. Redo the cleaning procedure till you see a spotless joint. To ensure no filtrate solder, use a solder wick to soak up the residue.

Note that, while desoldering the intersections, don’t use desoldering pump close to the SMT (small surface-mounted) constituents. Any suction and hotness surge might extricate the SMT constituents.

Step 4: Cleaning the Desoldering pump

Prime and actuate it for some time as you prepare for washing. Moreover, that ensures the bar shoves over the plunger and the solder doesn’t congest.

Besides, to wash it out more comprehensively, you can dismantle the pump holding the plunger by its gnarled verge. Unscrew it by twisting the counter-clockwise. After removing the nozzle, clean the pump interior.

Soldering and desoldering tools

How to Desolder a Circuit Board

The process might be a tiresome activity regardless of the reason. You need to use conventional equipment such as a solder sucker with sharp vision and firm hands.

The essential process involves;

-

Choose Precise Soldering Iron

It would help if you chose an iron that displays the digital temperature on the monitor. Besides, to ensure a level movement, ensure it has supple wiring and connection and has a clean tip. Else, it will decrease iron’s performance or its transmission property.

-

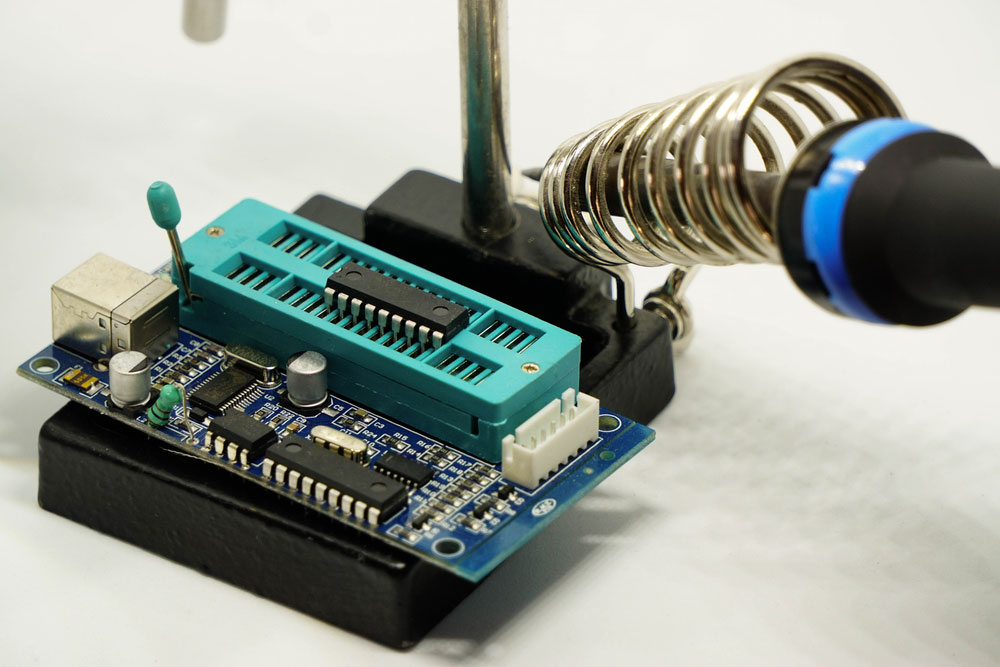

Purchase Proper Circuit Board Holder

It’s essential to have a holder proficient in maintaining the electrical circuit board. Besides, remember you are handling a tiny-sized space, thus, requiring a high level of precision. Therefore purchase a holder with added caution as the process has to be fast and error-free.

-

Use Solder Vindicated Magnitudes

Solder helps the procedure of getting rid of the board’s constituents easier. Therefore, as you use it in ideal quantities, you quicken the process of desoldering the board or getting rid of the components. Furthermore, if you use additional solder, it might need a higher temperature for melting hence added duration for solidifying. Thus, if you don’t use the suitable solder quantity, there is a high possibility of destroying the PCB. Therefore, select the proper quantity according to the PCB density.

Soldering kit

-

Be Prompt

You don’t want to overexpose yourself to vapors and lead for an extended period. Therefore, execute the desoldering procedure quickly.

-

Disconnect the Circuit Board

It's essential to disconnect the PCB or detaches rather than struggle with the device. Besides, you need to perform the process in a well-aired space. In addition, you will have a quick desoldering process and enhanced space for movement.

Best Desoldering Pumps

With so many desoldering pump brands available in the market, you might be wondering where to start. We have listed the four best ones to help you find the right one.

-

TABIGER Desoldering Wick & Pump

Robust and high-quality suction, desoldering Wick is a strenuous vacuum pump with Aluminum Bronze Frame. Besides, it’s a durable, high-quality soldering iron tool with good heat shields dispersion and high corrosion resistance. It has a geometrically defined interlace with rosin and copper. Hence even after using it for quite some time, it shows no bending or nicking.

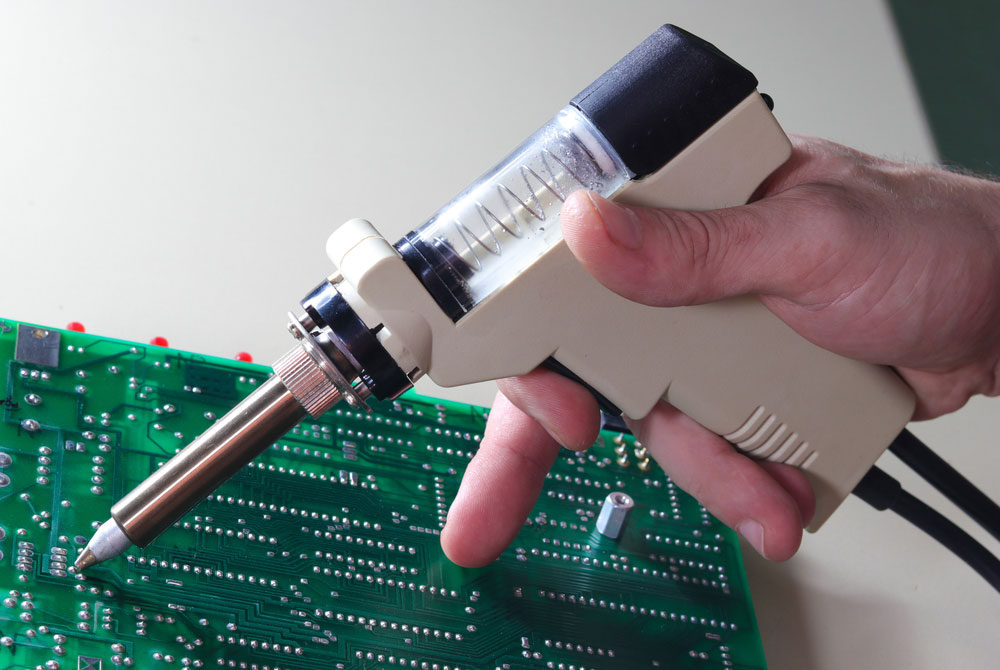

Professional tool solder sucker for solder removing and desoldering

-

Solder Sucker- desoldering pump

The pump is an excellent lightweight, a handy tool that fits all your De-soldering needs. In addition, it’s an anti-static device with a heavy-duty aluminum housing and a replaceable nylon tip. Besides, it’s ideal for use in industry, home, schools, service shops, labs, etc.

-

TBBSC Desoldering Pump Solder

A perfect diminutive solder chump that sucks the solder away quickly. Besides, it’s an ideal bit of suction, and you can reset it and suck using your thumb. It features a back pull design for internal mechanism prompt suction. Besides, its simple desoldering pump design allows for compact suck and tranquil one-handed operation.

Tin suction pump

-

Les now Solder Sucker Desoldering Pump

Primarily used in electrical and electronic industries, Les now is suitable for integrated circuit pins, digital repairs, home appliance maintenances, etc. Its ergonomic design makes its grip comfortable, operation not slippery, and usability convenient. Besides, it’s a high-quality and robust device suitable for lasting use and good solvent resistance.

Summary

Desoldering procedure is an essential process. If you have a poorly soldered joint, it might lead to electrical circuit failure with time. Therefore, ensure you understand the process properly to complete the process without damaging your PCB carefully. If you have any queries, reach out for further clarification.

Special Offer: Get $200 off your order!

Email [email protected] to get started!