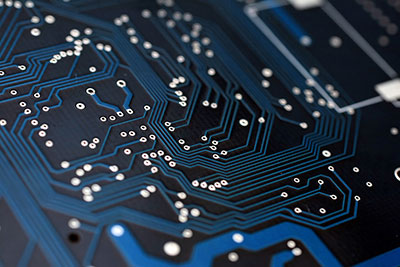

A printed circuit board or a PCB is a board that connects electronic parts for better functionality of an electrical device.

A PCB is the primary building block of any electronic design and, over recent years, developed to become very sophisticated components.

However, PCBs differ in some ways. There are conventional PCBs and advanced or high-level PCBs. Unfortunately, though, plenty of distributors and wholesalers in need of advanced PCB have little to no knowledge regarding their application areas, production, and ordering channels, to mention but a few. Below, we have this informative guide touching on ten essential things to know regarding advanced PCB.

(A designer holding in hand an advanced circuit PCB)

Contents

- 1. Industries Covered by Advanced Circuits

- 2.Selection of Advanced Circuits Materials

- 3. Advanced Circuits Special Size

- 4.Type of Advanced PCB

- 5. Demanding Operation Steps of Advanced PCB

- 6.Advanced PCB Production Equipment

- 7. Complete Advanced Circuits Test Standards

- 8.Life of Advanced Circuit Boards

- 9.Future Development Trends of Advanced PCB Circuits

- 10.The Choice of Advanced PCB Manufacturing Firm

- Summary

1. Industries Covered by Advanced Circuits

When comparing the industry coverage between ordinary printed circuit boards and advanced printed circuit boards, you’ll discover that advanced or high-level PCBs find much use in plenty of industries. Unlike regularly printed circuit boards, advanced PCBs find a lot of use, especially in high-end electronic components where speed and precision are paramount. Ordinary printed circuit boards find application in:

- Watches

- Carbonless copy paper

- Adhesives

- Tapes

On the other hand, high-level or advanced printed circuit boards find a lot of use in areas such as:

- Industrial equipment – to allow for greater precision, the safety of workers, and faster operation of an equipment

- Automotive Electronics – to hold the entire exquisite sensors and components needed for steady operation of a vehicle

- Communication equipment – for purposes of routing signals and power

- Medical facilities – used to assist medical equipment to monitor body temperature or heart-related application devices.

- Military field- they are fundamental towards the operation of guidance, military navigation, and control of warfare equipment.

(Uses of advanced PCB in the production of medical-grade electronics)

2.Selection of Advanced Circuits Materials

Again, when making a comparison between ordinary printed circuit boards and high-level or advanced printed circuit boards, you will notice that the type of material used between the two of them differ a lot. Advanced printed circuit boards work in environments where power and heat are incredibly high.

Additionally, they find much use in the background or equipment that tends to vibrate a lot. For this reason, the choice of material to use in high-level or advanced printed circuit boards differ when compared to content that ordinary printed circuit boards use.

Advanced PCBs require materials that can handle power and heat effectively.

When it comes to advanced printed circuit boards, the choice of material to use is meticulous. Some of the best articles that meet international standards and suitable for advanced printed circuit boards are the 3M, Rogers materials. Others are RO4360G2 and RT/droid 6035HTC circuit materials.

(A technician working on the production of advanced circuit boards)

3. Advanced Circuits Special Size

Unlike conventional printed circuit boards that may come with many errors and faults, such shouldn’t be the case when working with high-level printed circuit boards. As mentioned earlier, high-level PCBs find a lot of use in plenty of applications where precision, high-performance, or accuracy is paramount.

Therefore, when it comes to designing senior printed circuit boards, you need to pay attention to whether your choice manufacturer can effectively meet the specific size requirements that you may want your board to have. Is the thickness correct? What about the number of layers? When designing high-level PCBs, the errors should be minimal to none, if possible. The reason behind this is that these are not ordinary boards work in light equipment.

(an engineer working on the specifications of an advanced PCB)

4.Type of Advanced PCB

When looking at printed circuit boards, you’ll notice that there are different types of them in the field. Each one of them has its manufacturing specifications, usages, and the variety of materials used. When it comes to designing advanced printed circuit boards, the number of layers matters the most. Why? It is all about performance. For instance, double-layer high-level PCBs will perform better than single-layer advanced PCBs. The following are the types of superior PCB products:

- Multilayer boards –Consists of up to three or more double panels stacked on top of each other. Theoretically, these can contain as many plates as needed.

- Rigid and flexible boards – rigid boards that cannot twist or ben and typical for applications where bending is unnecessary. Flexible boards can bend easily and are used in applications where bending is a must for electronic devices.

- High-speed signal transmission is circuits whose length of the rising and falling signals is higher than the transmission line length.

- High-frequency boards – these PCBs carry high-frequency signals that are mainly above 1GHZ. They are somewhat expensive and usually cost around $0.6 per square centimeter.

(application of advanced PCB in a real-life scenario)

Special Offer: Get $100 off your order!

Please email [email protected] for details.

5. Demanding Operation Steps of Advanced PCB

Advanced printed circuit board fabrication is one of the most tasking exercises that designers undergo. Transforming a printed circuit board design from its layout to a physical structure is not easy. When it comes to high-level printed circuit boards, there are several demanding operation steps that designers need to pay attention to them. Some of the most demanding steps that require timing and precision include:

- Micro-holes drilled by holmium laser- advanced PCBs have plenty of micro-holes within them. Drilling these holes is a demanding step that calls for highly mechanized equipment such as a holmium laser.

- Cavity board – attempting to reduce the space covered by the motherboard is quite tasking. PCB designers face a lot of challenges when it comes to lowering board thickness, another demanding operation in the manufacture of advanced PCBs

- Heavy copper – heavy copper PCBs are used to power supply systems and electronic devices. It is a demanding step that requires precision and copper weight of more than 4oz

- Implantation of a thin wire circuit is the placement of a small wire circuit with a higher resistance, making it hard for electric current to move through it.

- IPC 3 etching – this is a method of preparing test specimens to determine bare dielectric material properties and quality by using cupric chloride as the etching solution to remove copper cladding

(Advanced PCBs that have undergone various production steps)

6.Advanced PCB Production Equipment

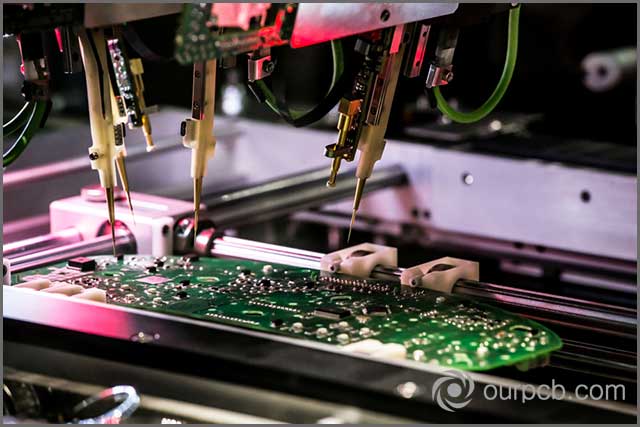

The manufacture of advanced printed circuit boards is an exercise that calls for specialized equipment suited for the job. If you go ahead and use substandard or equipment not fit for use, rest assured of producing a printed circuit board that lacks the name advanced in front of it.

From film sticking machine to etching machine to exposure machine, you must ensure that you use the best of the best devices in the field as a designer. The manufacture of high-level printed circuit boards requires the use of advanced equipment instead of using standard production machines that may see you producing substandard products during the final run.

(advanced equipment used in the manufacture of advanced PCB)

7. Complete Advanced Circuits Test Standards

After completing the design of high-level printed circuit boards, you need to conduct some tests first as a designer. Without having to test your PCBs, there are higher chances that you will release products full of errors and other manufacturing faults.

Tests enable you to identify such mistakes early and rectify them before publishing your products. There are specific standards that you have to adhere to strictly. They are known as the IPC standards. These standards are industry-adopted across the electronics field for PCB design, manufacturing, customer standards, and PCB assembly.

(Advanced PCB undergoing various tests after completion of its manufacture)

8.Life of Advanced Circuit Boards

There is a significant difference between printed circuit boards that find their use in high-tech industries such as the aerospace or the medical field and ordinary printed circuit board. High-level printed circuit boards are sturdy and designed to last. When compared in terms of shelf life, you will notice that advanced PCBs last longer than ordinary ones.

Materials and also the surface treatment of high-level PCB are different compared to ordinary ones. Also, high-quality equipment is used to produce high-level PCBs, a reason why they last a little bit longer than conventional ones.

(a sample of a durable and robust PCB)

9.Future Development Trends of Advanced PCB Circuits

The world of advanced printed circuit boards seems to be changing thanks to the new and emerging technological trends and rising demand for them across several industries rapidly.

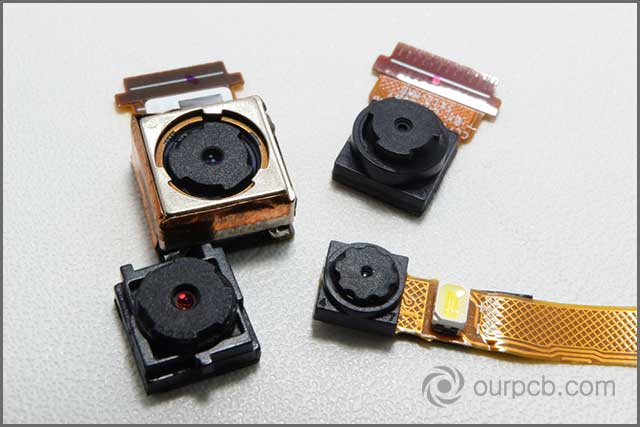

Again, it is necessary to be ready for the future of PCBs. It is essential to be aware of what the future has ahead of us. According to industry experts, though, the future of advanced PCBs will witness the production of high-speed advanced PCBs because we live in an era that calls for high- speed functionality in almost everything. Additionally, we are most likely to witness PCB board cameras in the future. These are boards that get fitted directly on the board to take pictures and make videos.

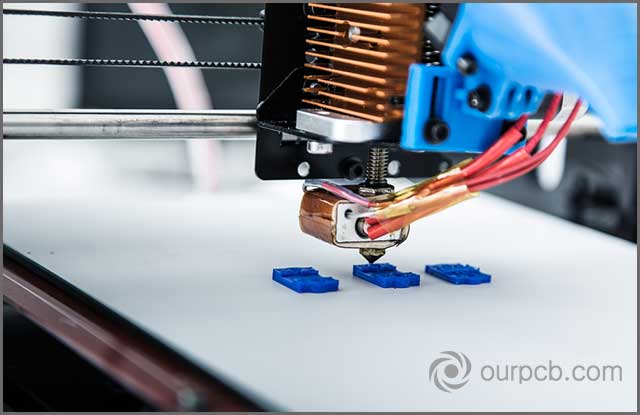

Furthermore, the future also seems bright for advanced PCBs with 3D printing technology is long-awaited. 3D printing is expected to change the electronic system's path and design high-level PCBs in the future. 3D printing can create PCBs by effectively printing substrate items layer by layer by adding several liquid inks and SMT technology to come up with a final board that can assume any shape.

(futuristic PCB 3D printer working on an advanced PCB)

10.The Choice of Advanced PCB Manufacturing Firm

When you are about to purchase your high-level PCBs, the manufacturer you choose to work with is something you need to keep at the back of your mind. You do not want to work with a broker or a firm that lacks experience producing high-level PCBs. After all, you are spending your hard-earned cash, and for this reason, you should expect high-quality boards.

If you are in the market for an experienced manufacturer to produce high-level PCBs for you, look no further than OurPCB. We have been in the industry for decades serving hundreds of thousands of clients. Our standards are certified, and our customer service is top-notch. We at OurPCB are familiar with everything about high-level PCB design in addition to being able to undertake fab and assembly in just one day. Contact us today for your senior PCB needs.

Summary

Advanced printed circuit boards are lately attracting massive demand across the industry when compared to conventional PCBs. The reason for this is because they find use in high-intensity fields where accuracy and precision are required.

While plenty of distributors and wholesalers in need of high-intensity PCBs know little to nothing about them, we hope that this article has educated you on essential things to know regarding high-level PCBs. Are you in need of advanced PCBs for your next project? We at OurPCB are prepared to assist you. Call us now, and let us help you.

Special Offer: Get $100 off your order!

Please email [email protected] for details.